Dam Inspections with Ground Penetrating Radar Technology

Due to the stresses caused by erosion, water load and water saturation, engineers are seeking reliable ways of probing the structural integrity of dams. Dams are critical structures that are built across waterways to control the flow of water. From small earthen embankments to large concrete structures, they are essential constructions for power generation, water supply and irrigation.1 Fractures and voids represent some of the most significant defects encountered in these dams. However, traditional investigation methods are invasive and destructive and only cover small areas. Furthermore, many discontinuities and anomalies are easily missed during a visual inspection and some issues wouldn’t be discovered without using non-destructive methods.

Non-destructive investigation methods that do not disrupt the normal operation of a dam are crucial to maintaining safety.2 To that effect, ground penetrating radar (GPR) is a non-destructive testing technique used for the investigation of fractures, fissures, voids, and other deformations in concrete and earthen dams.3 GPR enables the investigation of large areas of a structure while providing superior spatial resolution.

What is Ground Penetrating Radar?

RADAR (Radio Detection and Ranging) is a familiar technology that bounces radio waves off distant objects such as aircraft and ships to determine their distance and speed. In ground penetrating radar (GPR) systems, an antenna transmits high-frequency radio waves that are reflected by various materials and subsequently captured by a receiver.

GPR systems measure the time it takes for these radio waves to travel through materials and back to the receiver. The radio waves from a GPR system travels at a velocity determined by the dielectric permittivity of the material they encounter. During a GPR survey, an antenna travels across a survey line and records a series of data points which are then plotted to form a profile of the area.4

GPR is best in dry, sandy soils, rock, ice, and freshwater. However, in clay soils, penetration depth may only be a few feet compared to 30 feet or more in sandy soils. High frequency antennas generate high-resolution images but at a lower penetration depth, whereas low frequency antenna signals can penetrate deeper but produce coarser images.

Advantages of Ground Penetrating Radar

Inspecting a dam in Lapalisse, France. Photo Credit: ARKOGEOS

Compared with other non-destructive testing methods, such as acoustic emission testing, infrared thermography, microwave and ultrasonic-based techniques, ground penetrating radar offers greater depths of survey in less time.5,6

GPR operates across a range of frequencies in the megahertz or gigahertz ranges. High frequency antennas are useful for investigating reinforcement bars (rebars), fissures, small scale deteriorations, voids, and delamination. On the other hand, low frequency antennas are suited for investigating deep structures, large leaks, fractures, and voids. These low frequency antennas are also ideal for collecting large datasets, which would be difficult to obtain using more invasive techniques.

Special software is used to post-process and interpret data from GPR systems after the survey has been completed to identify the problem areas. This data gives dam operators the opportunity to conduct a critical assessment of dam conditions — including concrete deterioration and rebar corrosion — and take early action to prevent catastrophic failure. This GPR data can also be correlated with visual inspections and maintenance records to provide a complete picture of dam conditions.

GPR can also be used in combination with other ground survey techniques to provide complete assurance of structural integrity throughout a dam’s operational life.

Applications of Ground Penetrating Radar

GPR has been used to perform non-destructive geological, environmental, and dam evaluations for decades. It is valued as a tool for producing accurate data on structural profiles and repairs required while reducing costs, labor, and time.

Concrete inspection is fundamental to identifying and prioritizing structural defects that must be repaired. GPR is used to pinpoint deterioration in concrete slabs and determine the types of reinforcements required. GPR is an invaluable non-destructive tool in the investigation of dam integrity, enabling the effective identification of structural defects for swift remedial action at minimal cost and risk.

Surveying the CuaDat Irrigation Dam

Inspecting the CuaDat Irrigation Dam with a GPR system. Credit: Vucico Vietnam

Vucico Vietnam participated in the investigation of the CuaDat Irrigation Dam in Vietnam over several years. The 1,023 meters long and 119 meters high dam forms part of the CuaDat Reservoir built between 2004 and 2009 on the Chu River, southwest of Hanoi. The reservoir supplies water for domestic and industrial use and 86,000 hectares of agricultural land. The scope of this survey was to scan the entire surface of the dam, and the work was conducted over the course of several years.

During this dam inspection, Vucico used two different GPR antennas; 900 MHz and 2700 MHz. The team used the SIR 30 with a 900 Mhz antenna to identify possible voids and the StructureScan Mini XT ,that has a 2700 Mhz antenna built into the system, was used to locate exisiting rebar for better resolution.

Investigating Artificial Levees

Artificial levees are critical components in flood defenses. Structural defects in these levees can seriously compromise their effectiveness. In Hungary, where one-third of the country is protected by a 4,200 km long levee system, GSSI’s SIR® 3000 GPR unit with a 200 MHz and a 270 MHz antennas were used to investigate these levees.

Performing a fracture assessment to detect leakage zones in the concrete. Photo Credit: Szeged University

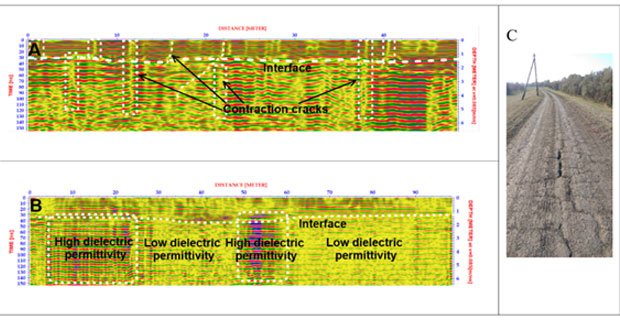

“GPR is strongly suggested here to survey parts of the levee as it gives a more realistic image of the subsurface settings of the study area. The GPR survey was conducted using SIR 3000 control unit (Geophysical Survey Systems Inc.) attached to a 200 and 270 MHz center frequency antennas in the survey wheel mode. Each GPR profile had a length of 100 m. Profiles were successive, meaning that the endpoint of one profile is the starting point of another profile.

After processing, the GPR profiles were analyzed in detail to identify interfaces and to record different types of anomalies. Anomalies were then categorized and evaluated in terms of flood risk. The spatial distribution of the different categories was analyzed in relation to other parameters referring to levee health. Besides mapping structural differences and defects, changes in levee composition were also assessed, mostly by investigating the attenuation of signals.” – Diaa Elsayed, PhD student at Szeged University, Hungary.

A complete profile of the levees was formed from 100 meter length individual GPR profiles. From this, six different types of anomalies were identified and categorized according to their flood risk. Their spatial distribution was mapped and changes in levee composition were also assessed. The spatial distributions and frequency of anomalies were found to correlate with flood occurrences, demonstrating the capabilities of GPR in anticipating flood risks.

Representative profiles for the identified GPR anomaly types: A) contraction cracks, B) remarkable changes in dielectric permittivity, and C) Photo showing the contraction cracks on the levee crown. Credit: Szeged University

“In large earth dams, there is a dam core, filter, support embankment and slope lining. These structures vary on a case-by-case basis. Water always seeps through the dam, under the dam and around it. Problems arise when internal erosion begins, i.e., the flow of water is so great that it takes away ground material and forms corrosion in the dam structure. Noticeable deviations in GPR profile are a consequence of these kinds of problems. These are the undesirable findings we try to locate. Therefore, dam owners can plan for the right type of repair. In our opinion, GPR is a cost-effective tool for risk assessment.” – Terho Makinen of Suomen Maatutkapalvelu

Inspecting an earthen dam. Photo Credit: Suomen Maatutkapalvelu

Dam Safety Group

The Dam Safety Group (DSG) provides the widest range of geophysical and seismic techniques and technologies to address non-invasive investigation, maintenance and monitoring of dams, embankments and levees. DSG brings ground penetrating radar, resistivity imaging, seismic tomography, seismic monitoring and wireline borehole logging together. Find more information about the Dam Safety Group and a range of dam inspection technologies on their website: https://damsafetygroup.com/

Final Considerations

Ground penetrating radar is a non-destructive testing method that aids in inspecting the structural integrity of dams saving time and money. GPR can be used reliably with other survey techniques to provide a comprehensive view of dam failures.

References

- Association of State Dam Safety Officials. Dams 101. [online] Available at: https://damsafety.org/dams101

- Dam Safety Federal Guidelines. [online] Available at: https://www.fema.gov/emergency-managers/risk-management/dam-safety/federal-guidelines

- Loperte A, al. (2011) Ground Penetrating Radar in Dam Monitoring: The Test Case of Acerenza (Southern Italy). International Journal of Geophysics [online] 2011:1–9. Available at: https://www.hindawi.com/journals/ijge/2011/654194/

- Yazdani N, al. (2018) Field assessment of concrete structures rehabilitated with FRP. In: Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures. Elsevier [online] p. 171–94. Available at: https://www.sciencedirect.com/science/article/pii/B9780081021811000083

- Dong Y., al. (2011) Non-destructive testing and evaluation (NDT/NDE) of civil structures rehabilitated using fiber reinforced polymer (FRP) composites. In: Service Life Estimation and Extension of Civil Engineering Structures. Elsevier [online] p. 193–222 Available at: https://www.sciencedirect.com/science/article/pii/B9781845693985500079

- D., et. al., (2008) Nondestructive Techniques for Inspecting Concrete Dams and Spillways [online] Available at: https://www.hydroreview.com/hydro-industry-news/nondestructive-techniques-for-inspecting-concrete-dams-and-spillways/